June 2015 MDPO Dynamic Arch Assembly Prototype build by Stephen L Ward Skyrise Productions, Inc.

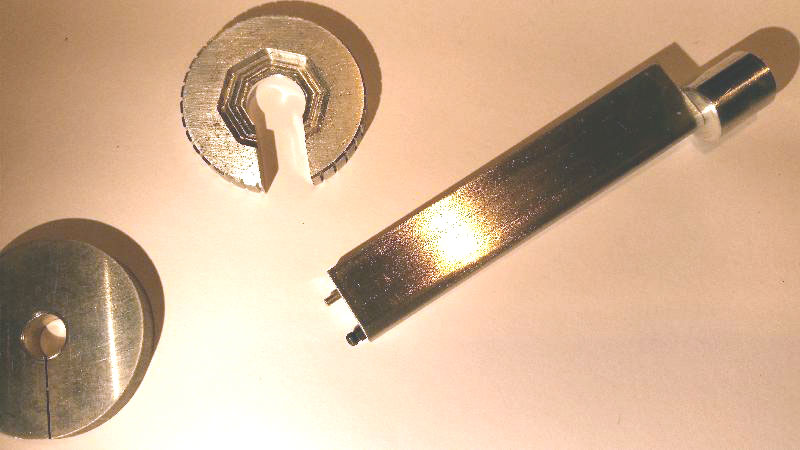

New wrenches for testing.

May 2015

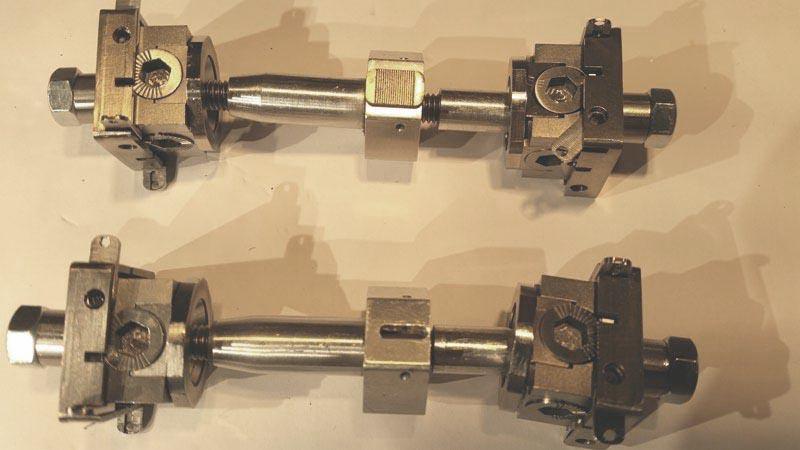

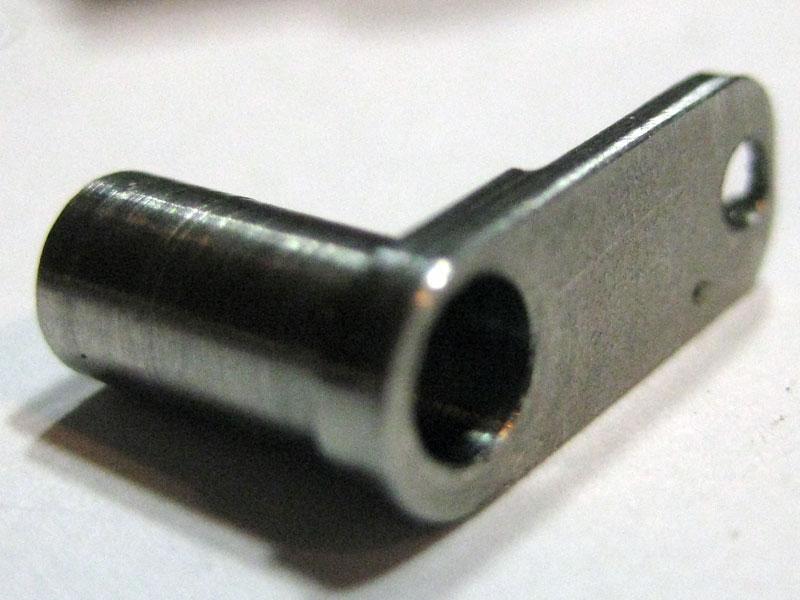

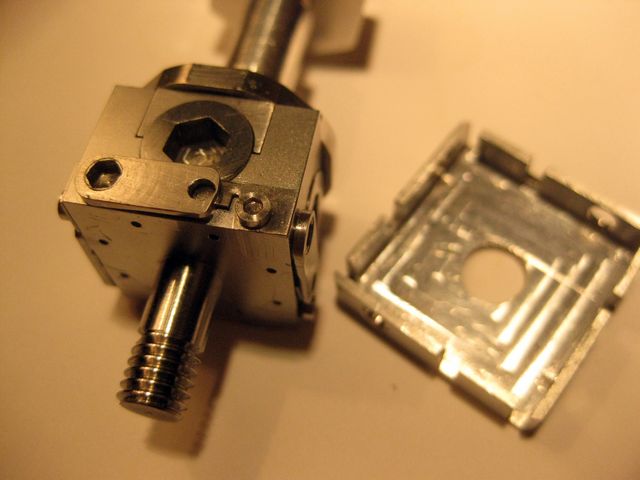

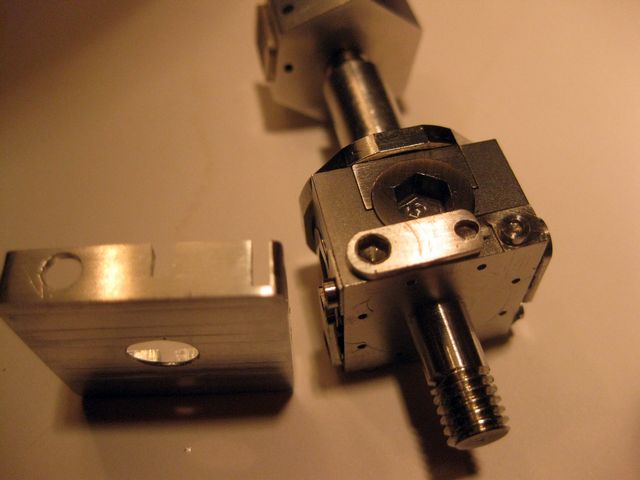

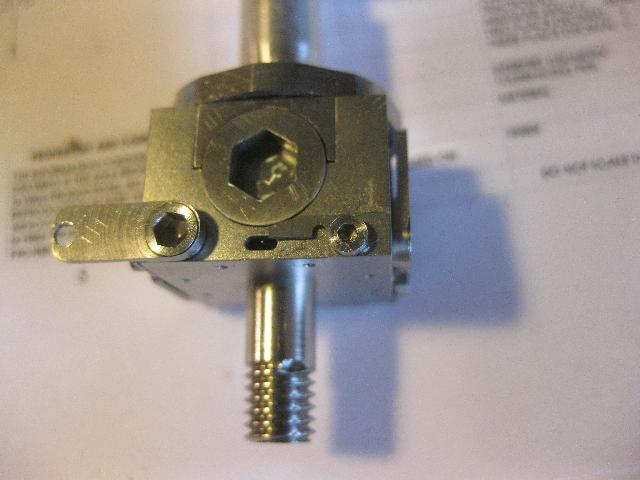

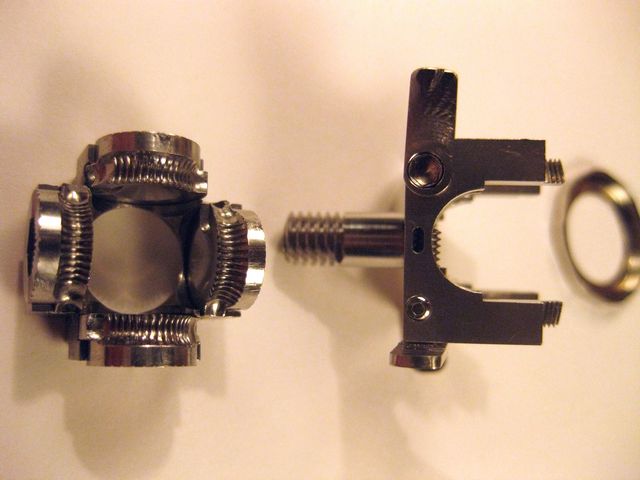

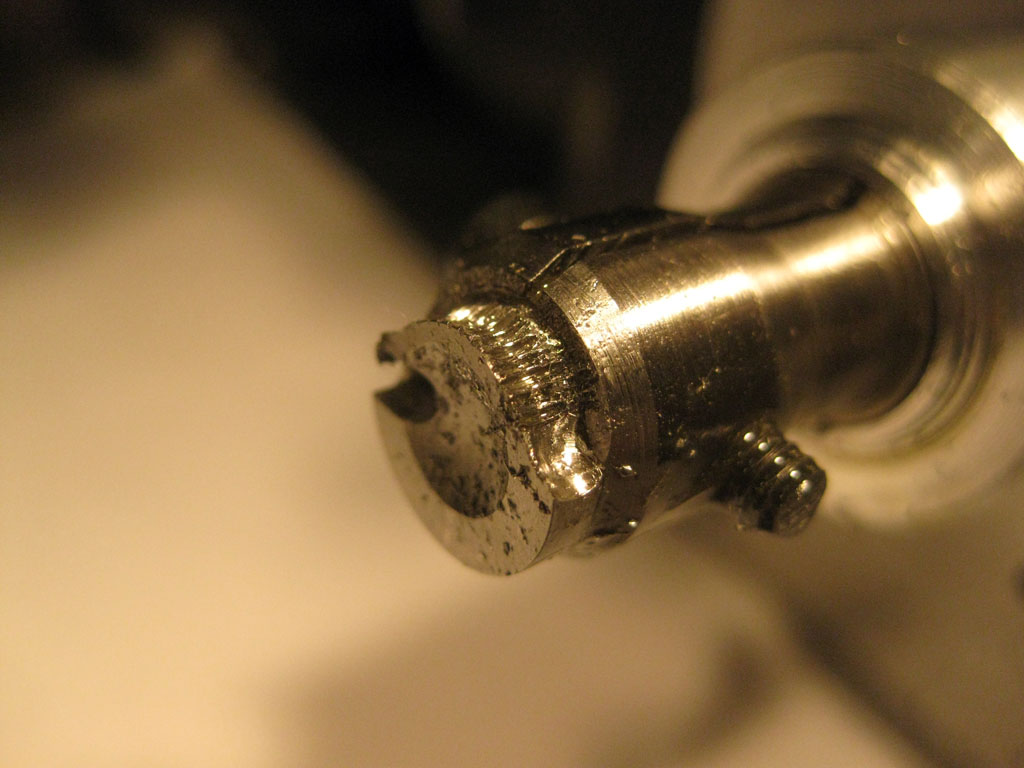

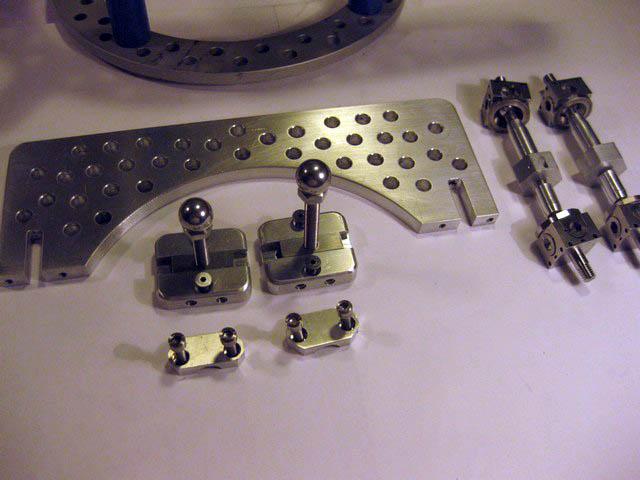

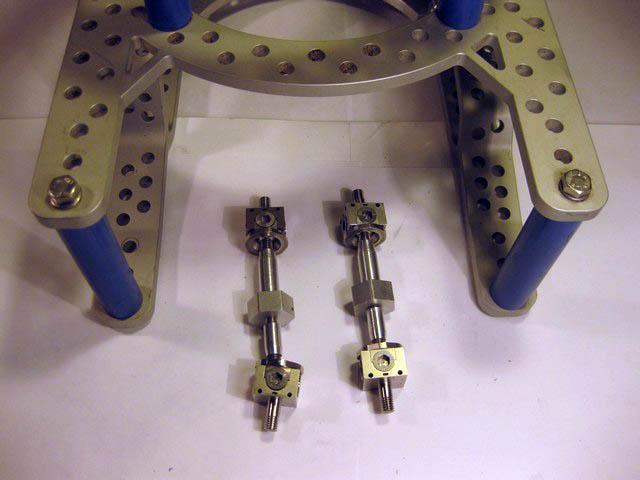

4 complete Ball Joint assemblies. Here I am replacing the switch buttons on the clickers.

These prototype buttons were brass, these new ones are stainless.

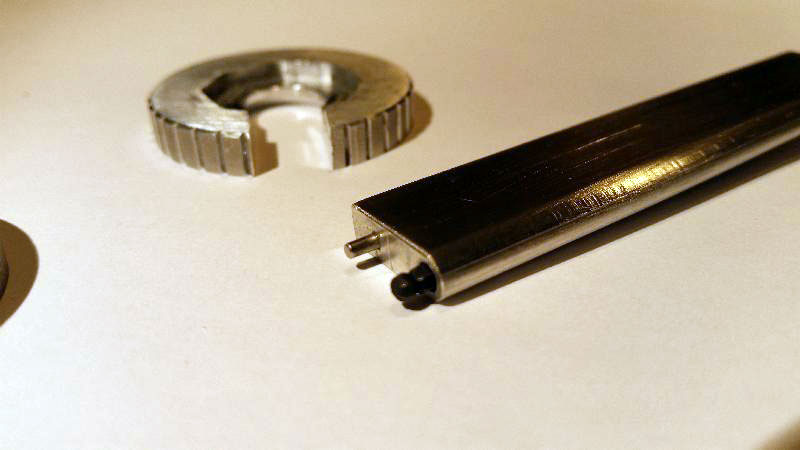

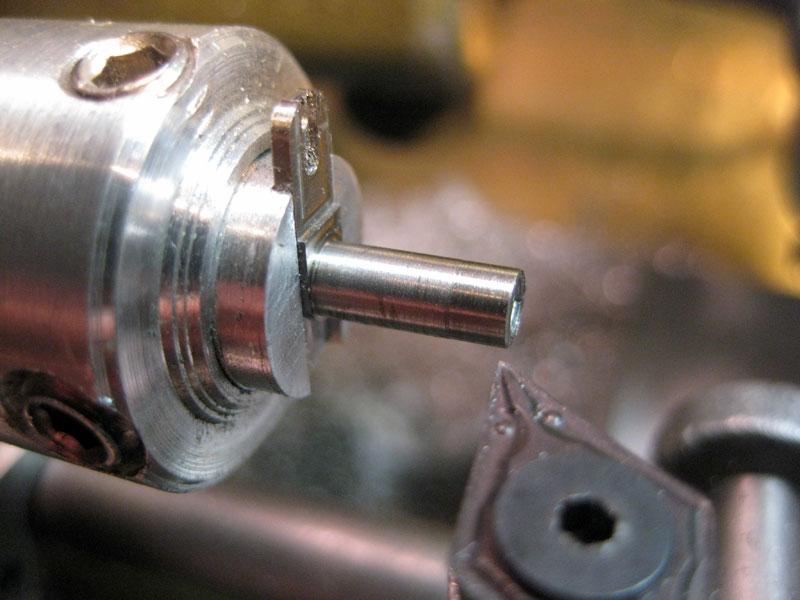

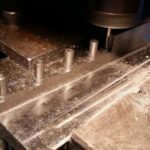

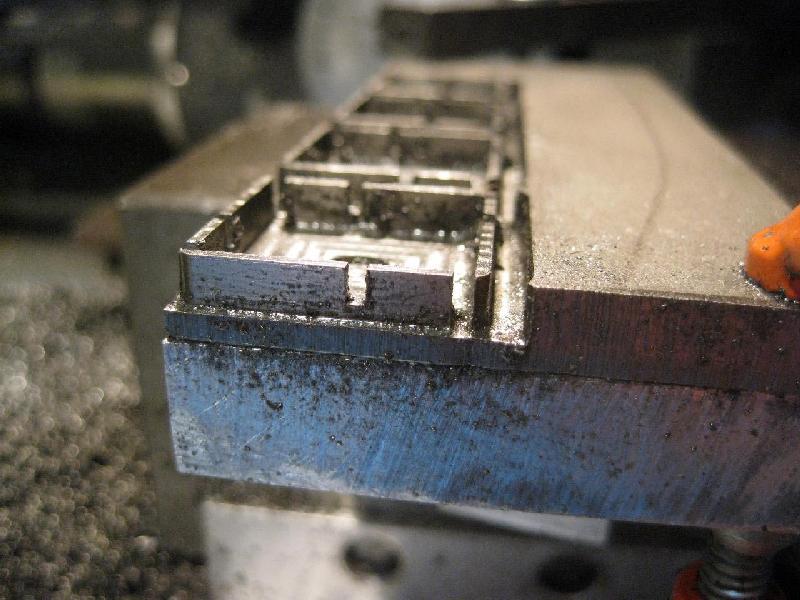

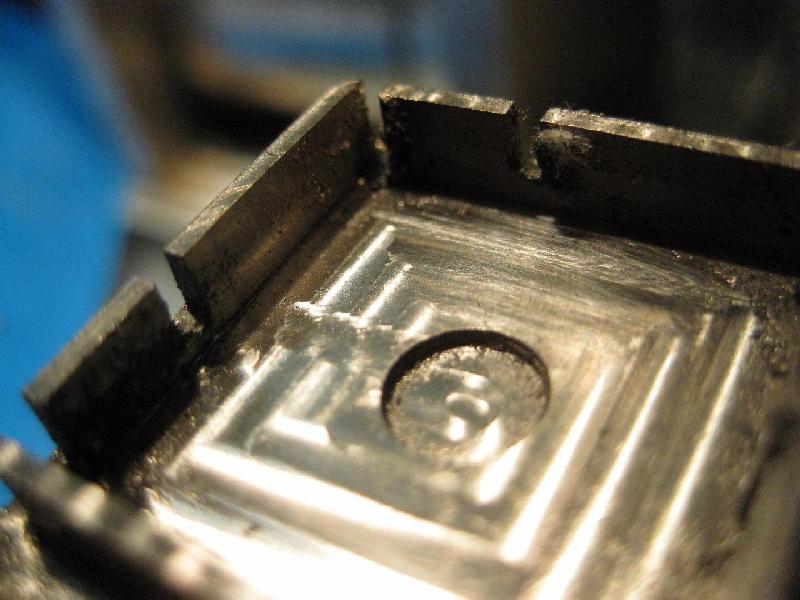

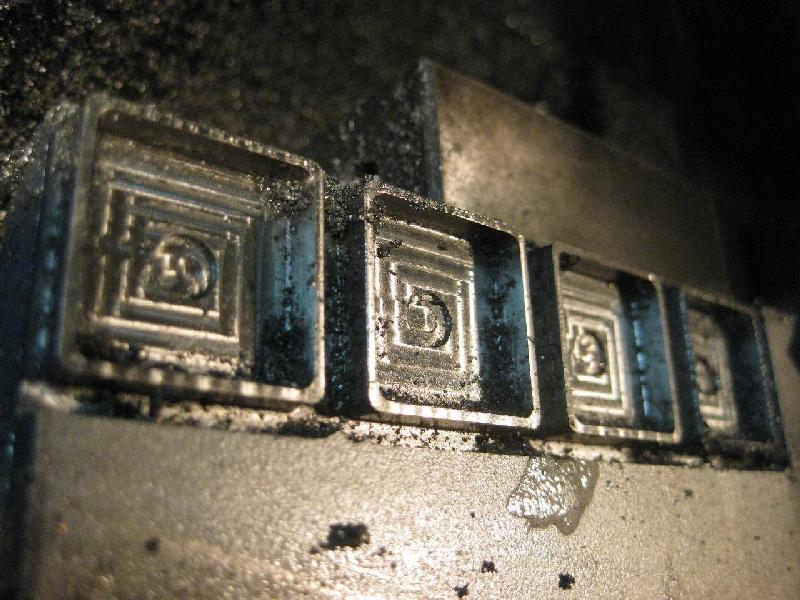

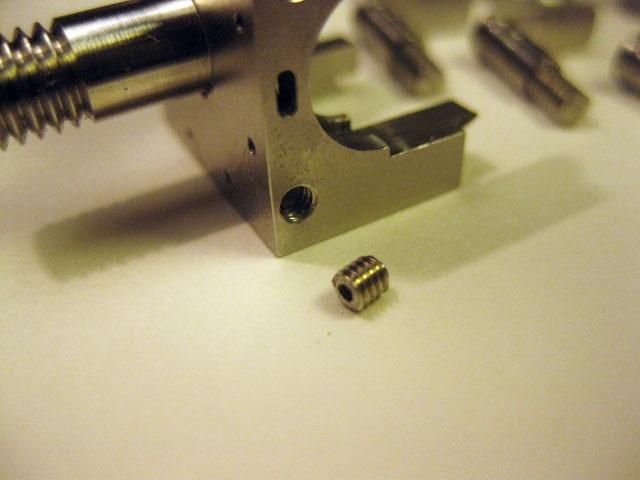

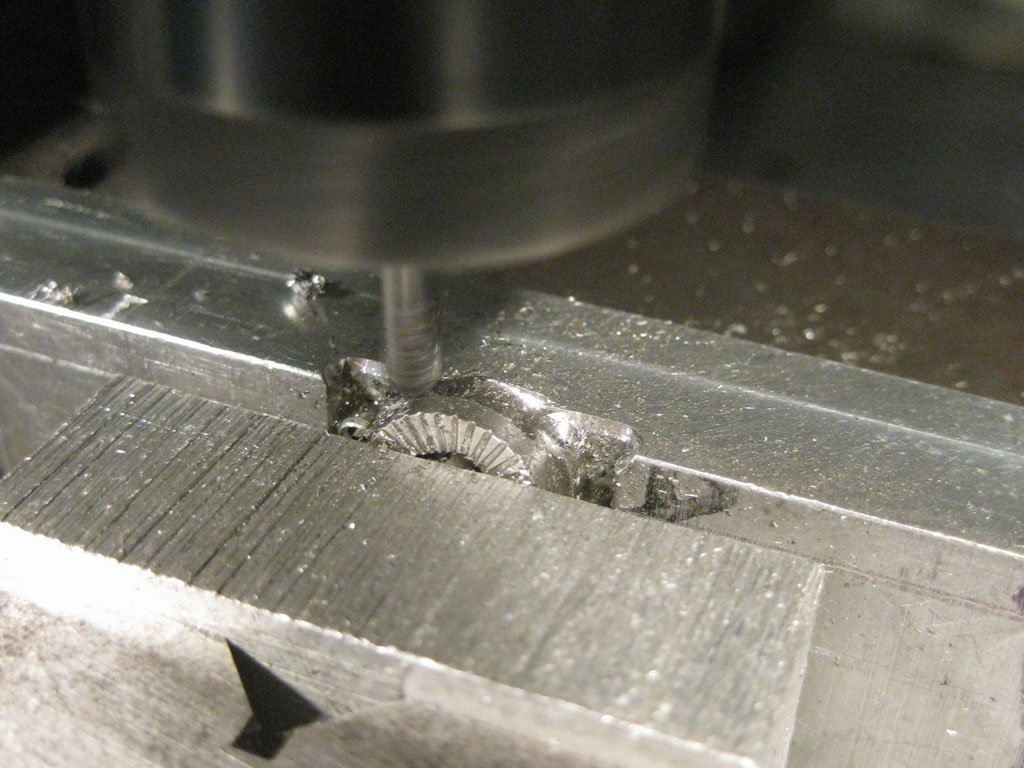

May 2015 gear cutting.

This is the last of the adjustment knobs to get teeth.

- Gears needing teeth

- Gear Blank

- Gear Blank

- Gear Blank

- Gear form Cutter

- Gear W/Teeth

- Gear W/Teeth

- Adjustment Knobs

Current Parts List:

|

Procedures pendingAll parts are fabricated for both left and right sets There are 8 adjustment knobs of the 16 that need the gear teeth cut, so we are currently cutting gear teeth. There is 1 ball joint ball that need the dowel pins installed. We have extra worm gears at this time. |

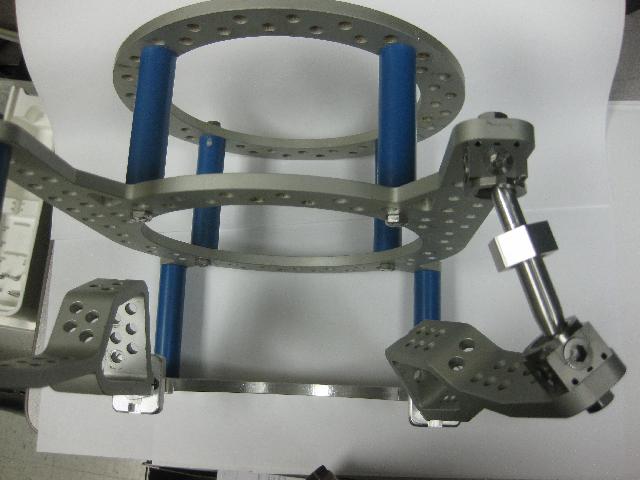

MDPO Dynamic Arch Prototype Construction

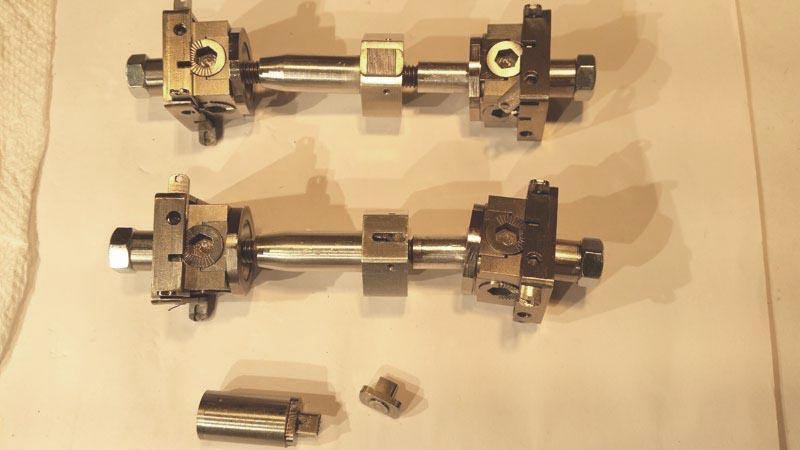

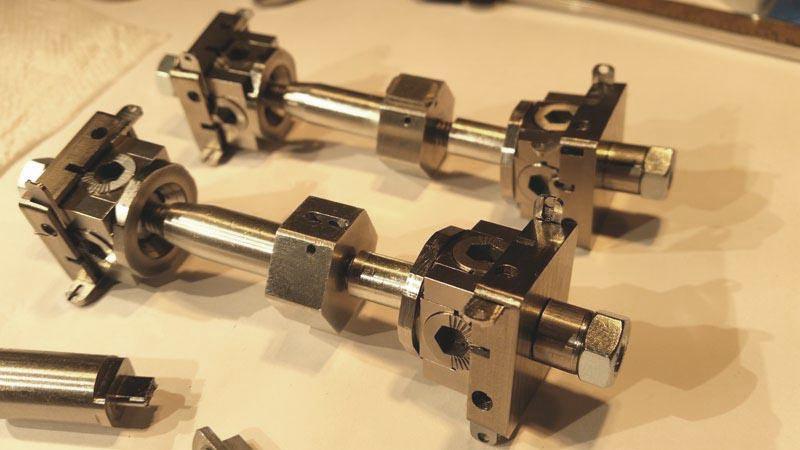

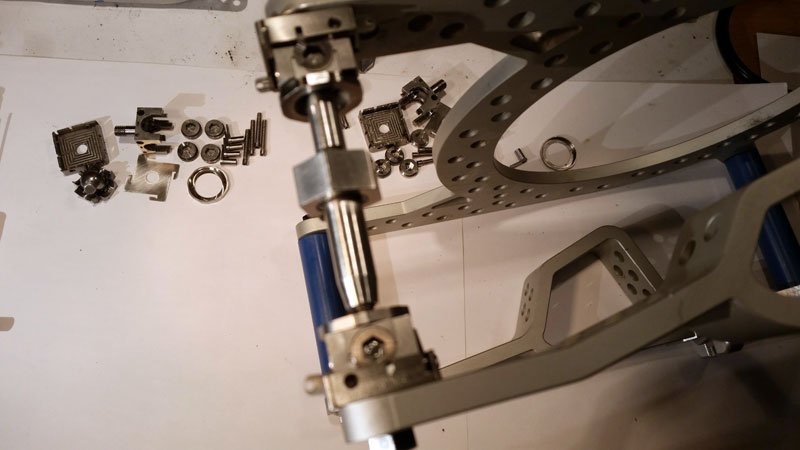

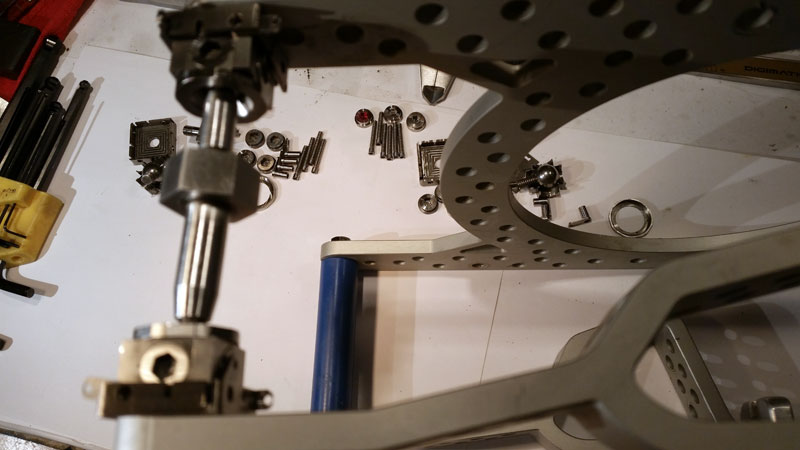

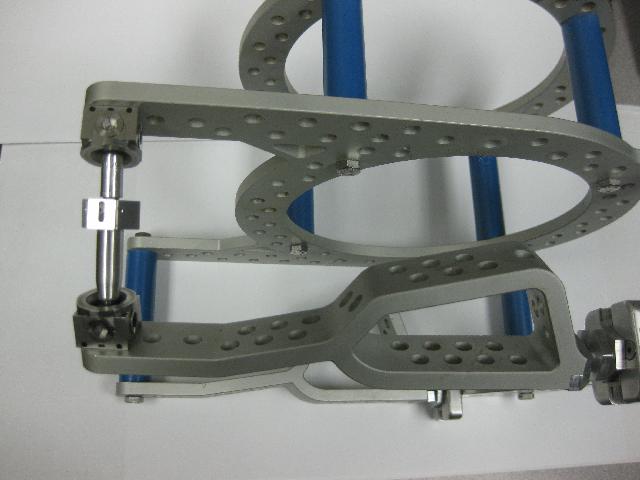

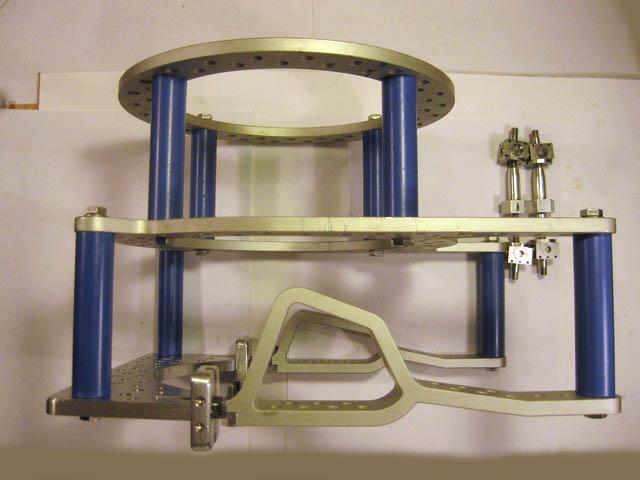

April 2015 We are assembling. This is the first side completely assembled

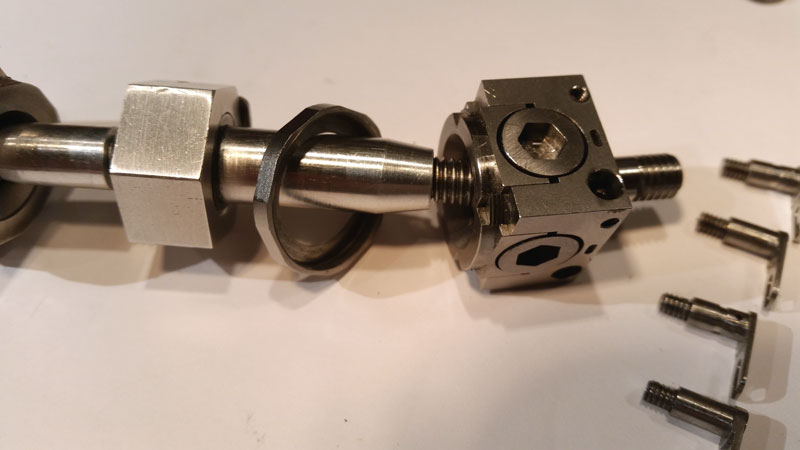

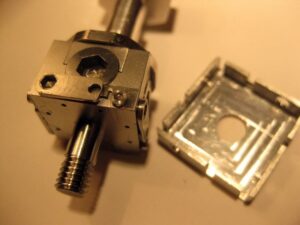

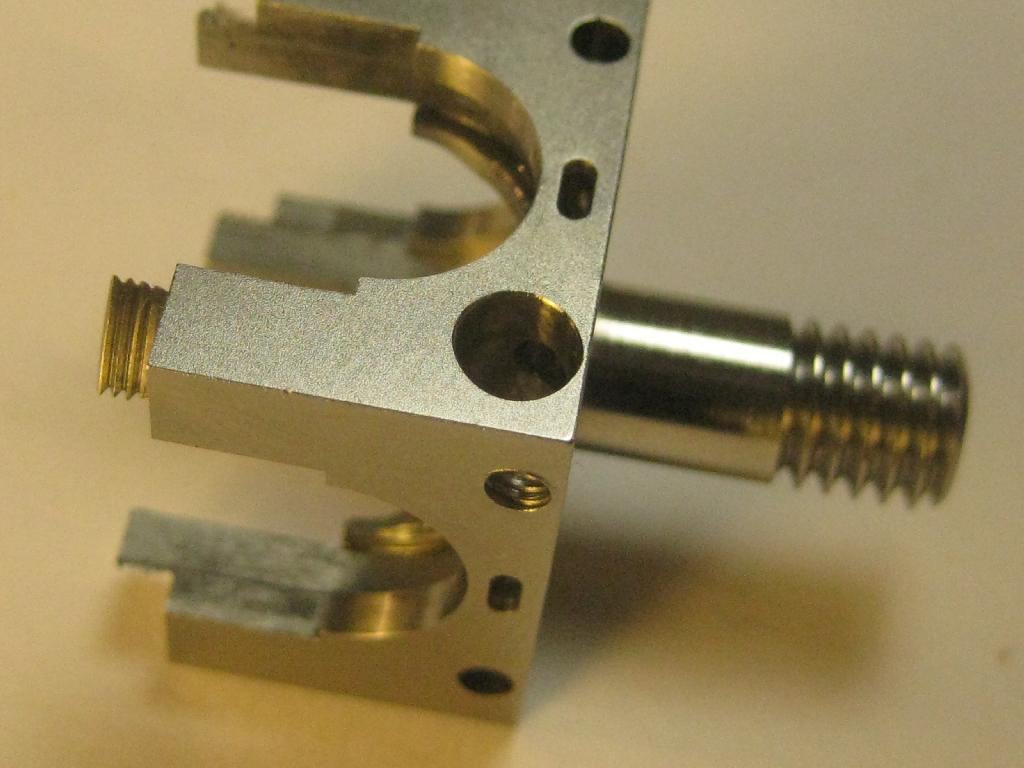

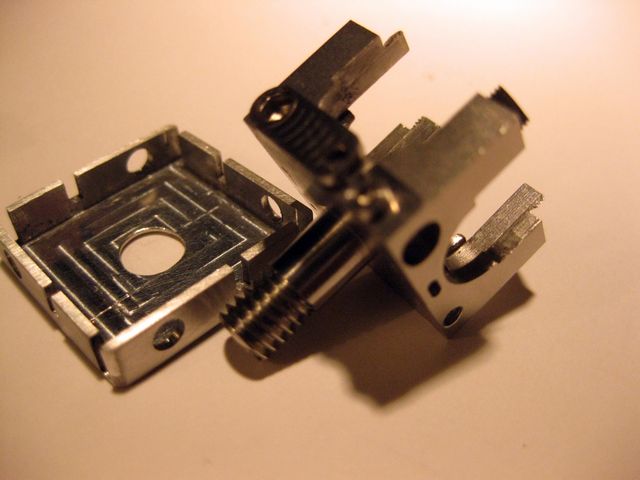

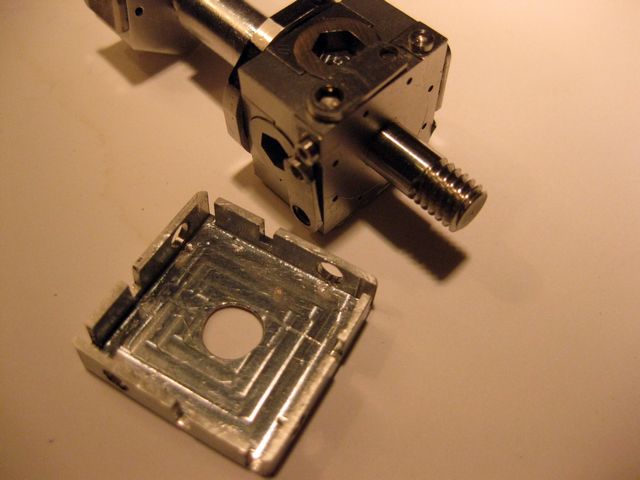

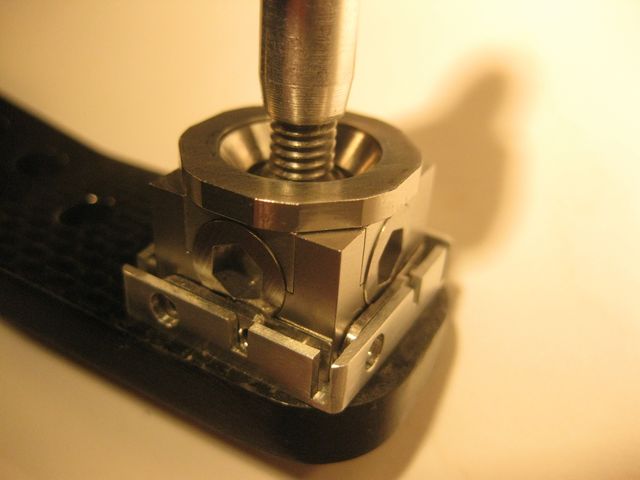

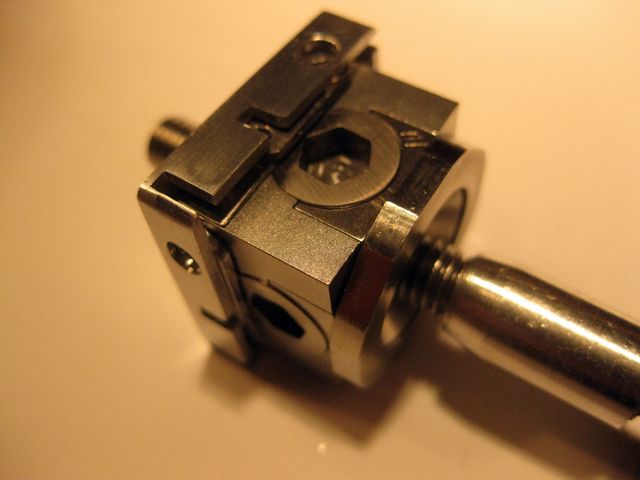

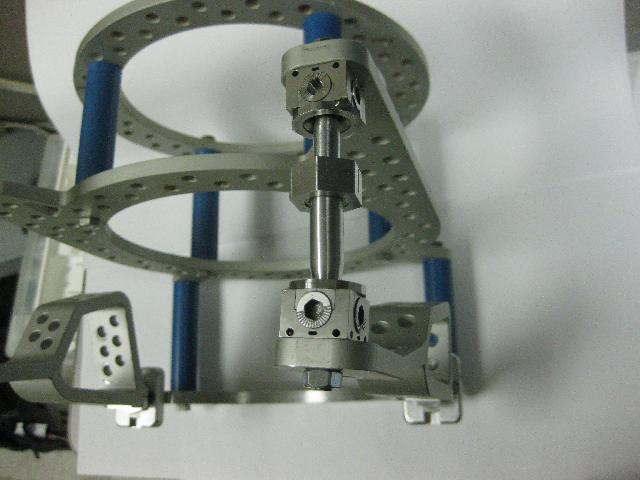

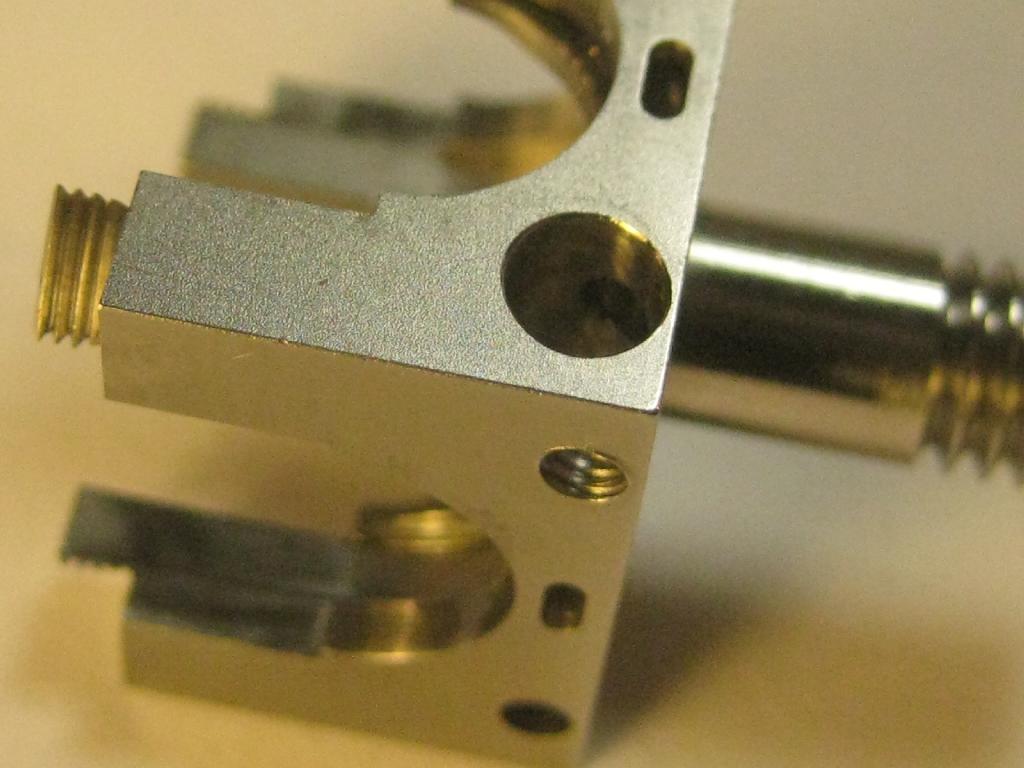

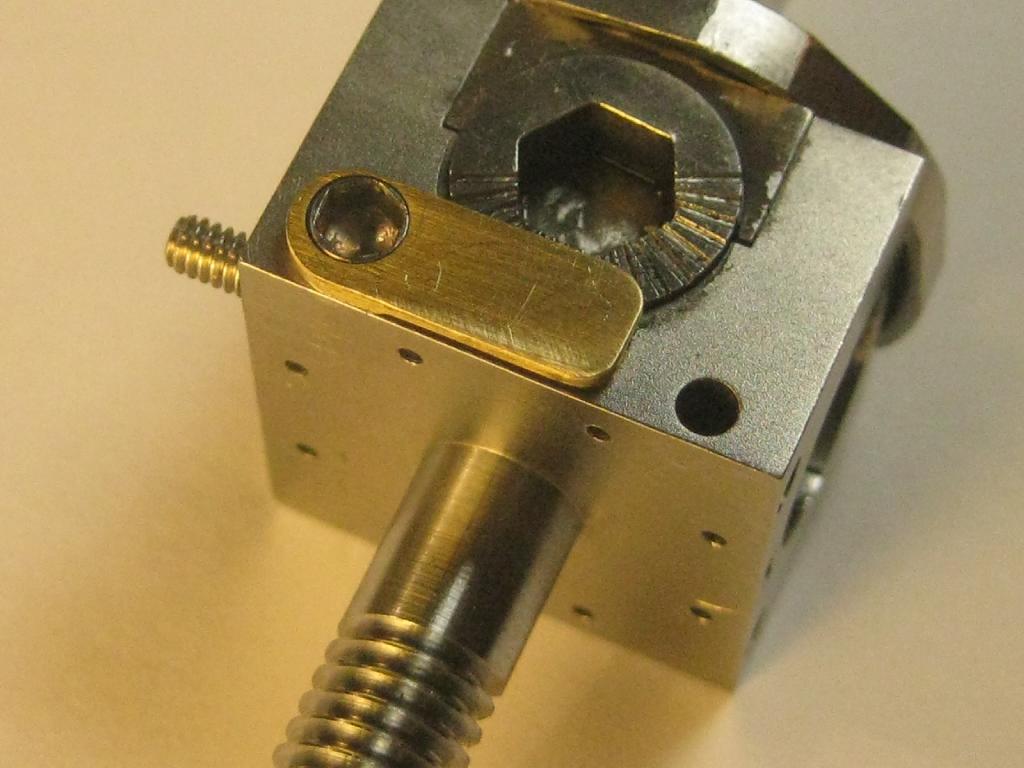

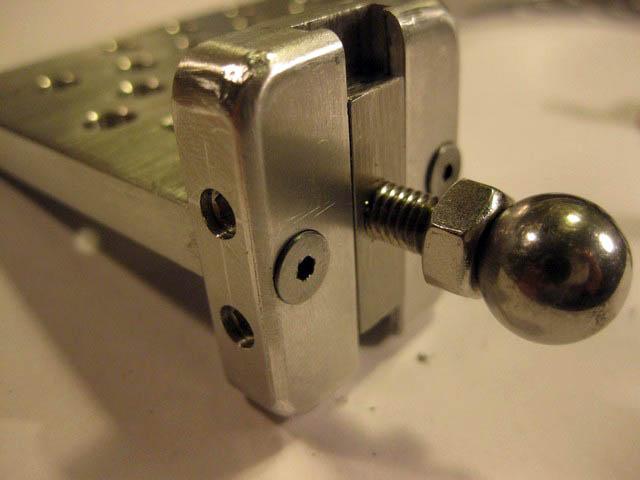

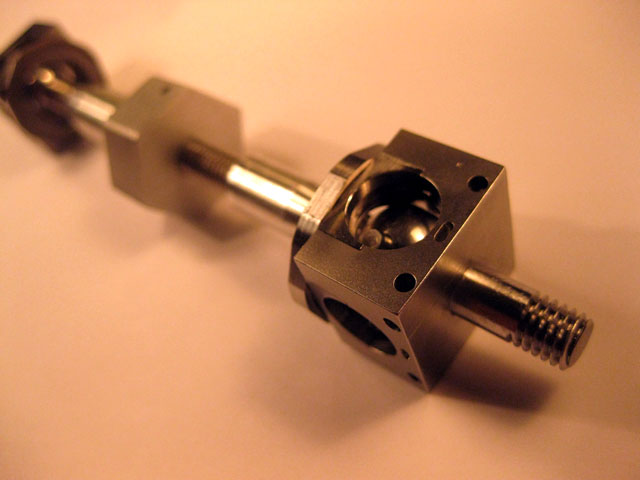

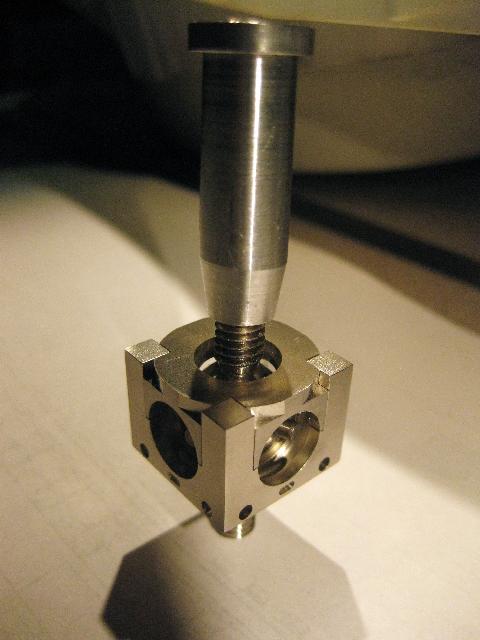

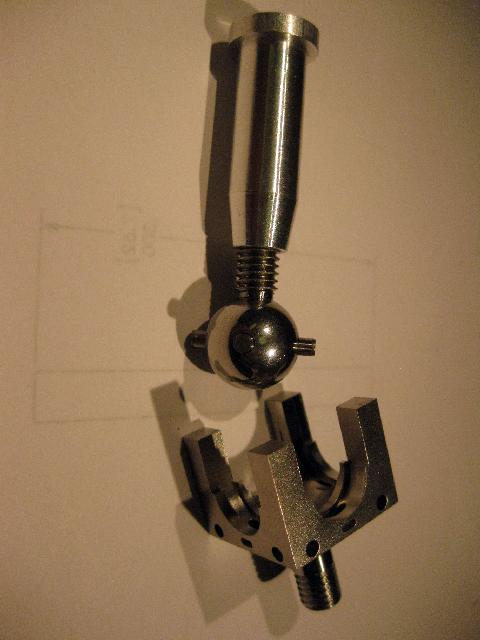

Dynamic Ball Joint Assembly

Assembly of a Ball Joint

We now have enough parts to build the first side complete

- MDPO Dynamic Column

- MDPO Dynamic Column

- MDPO Dynamic Column

- MDPO Dynamic Column

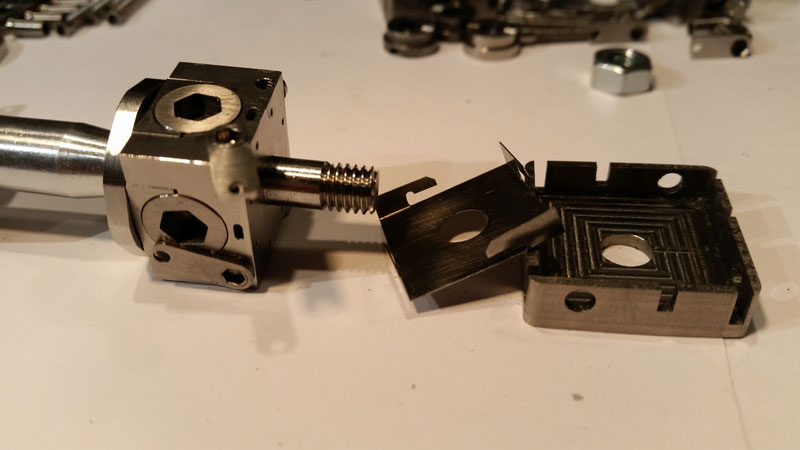

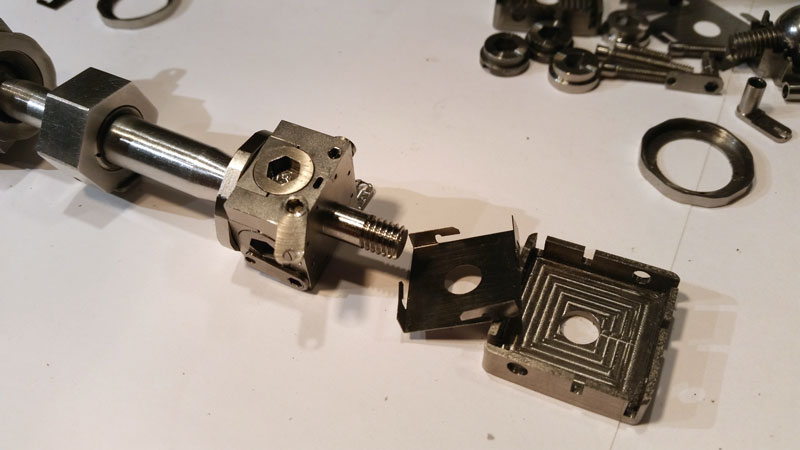

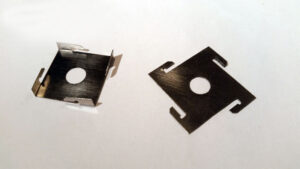

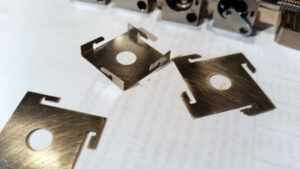

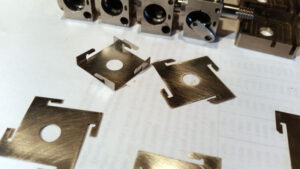

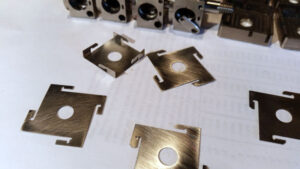

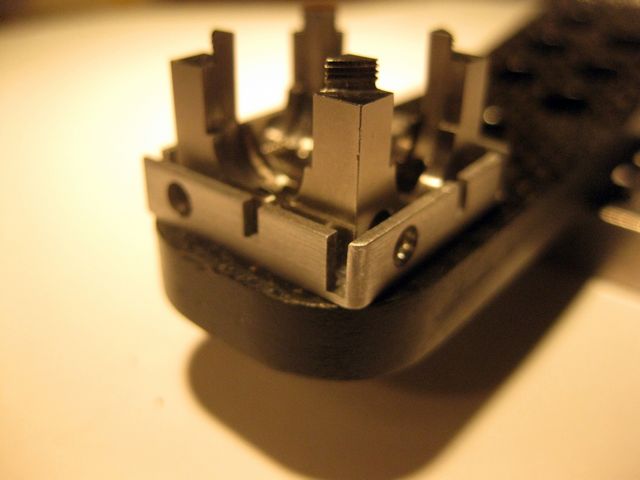

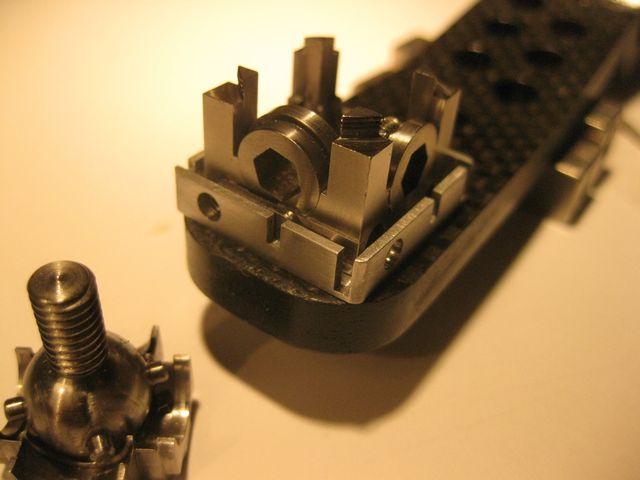

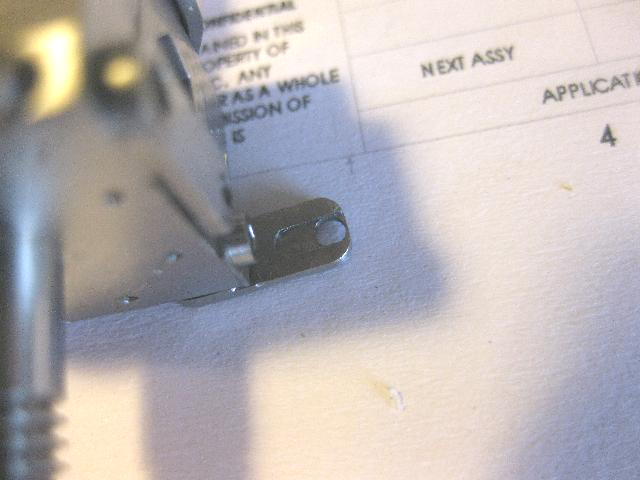

Spring clips

Major improvement for the locking clip that holds the lever locked.

- Bent New Spring Clip

- New Spring Clip

- New Spring Clip

- New Spring Clip

- New Spring Clip

- New Spring Clip

- Current Spring Clip

- New sheet for new clips

- Current Spring Clip

This spring eliminates the 4 current clips, 4 screws and 4 tapped holes in the housing, for each of the 4 ball joints. The sheet of stainless in the center picture is .007″ stainless spring steel. We need 4 clips like this instead of 16 of the little ones.

- Finishing Lever

- Finished Lever

- Counter Bore

- Bored for lever

- Boring housing for lever

- Boring housing for lever

- Boring housing for lever

- Boring lever for gear

- Boring lever for gear

- Levers with gears

- Levers with gears

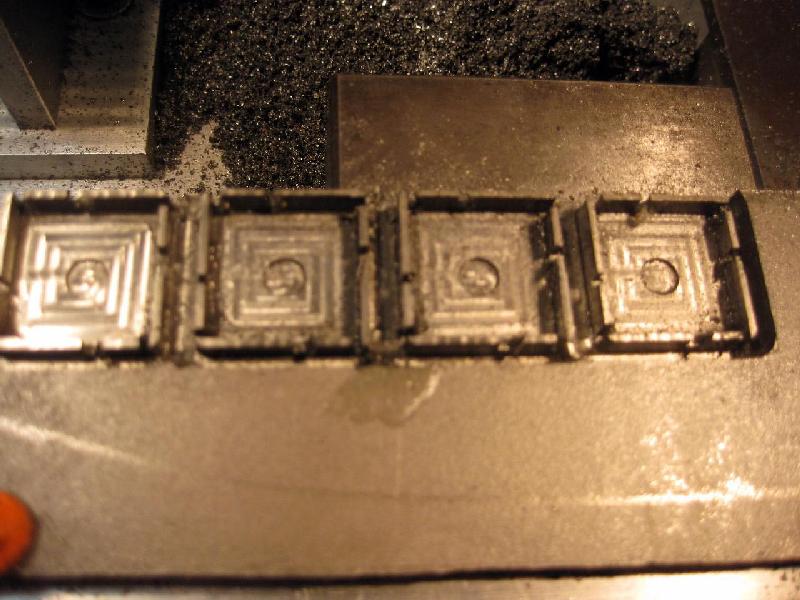

Levers ready for cutoff

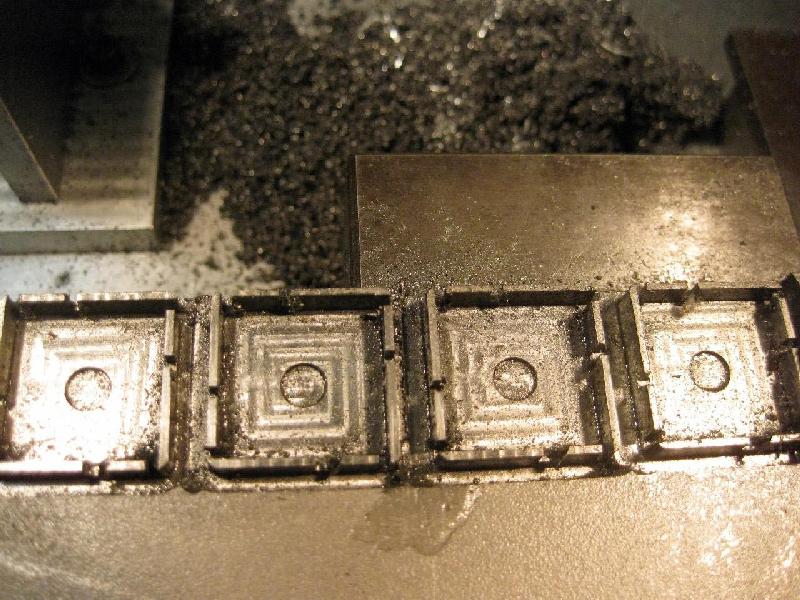

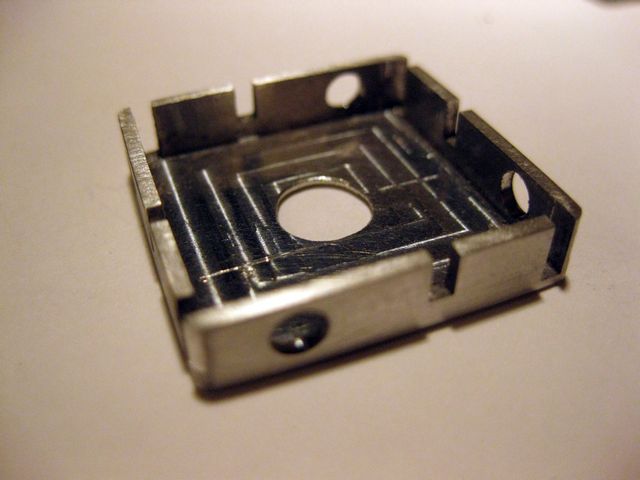

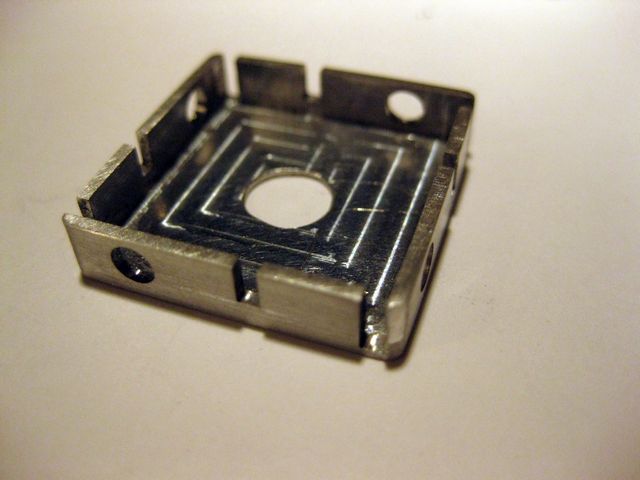

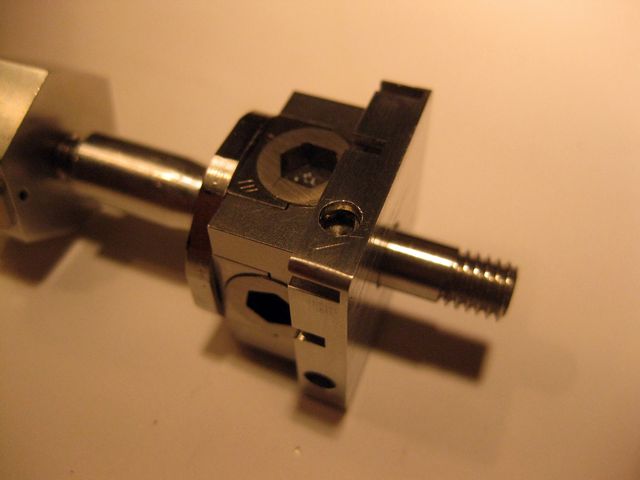

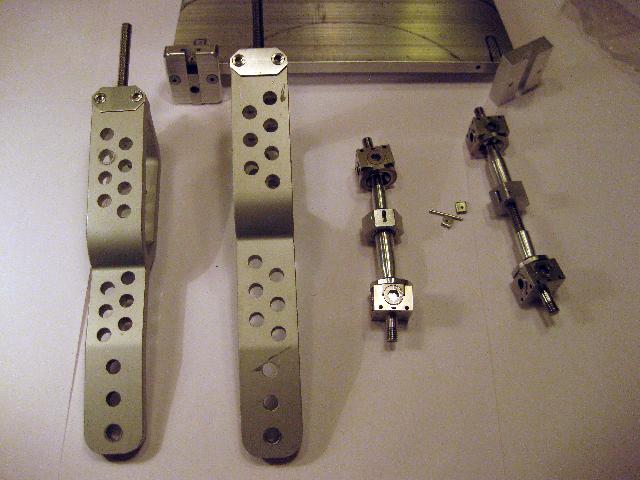

Feb 2015 We are working on Ball Joint levers

4 at a time and now opening the remaining housings for the levers.

Several of the first 8 levers and gears have slots and groves that are now not used with the new base plate design.

These are ready for boring the gear hole through.

This set makes 12 usable and we need 4 more.

- Boring lever for gear

- Boring lever for gear

January 2015 : 4 New Titanium Base Plates. These are much more durable than the aluminum prototype shown center. Still to be released from the titanium bar.

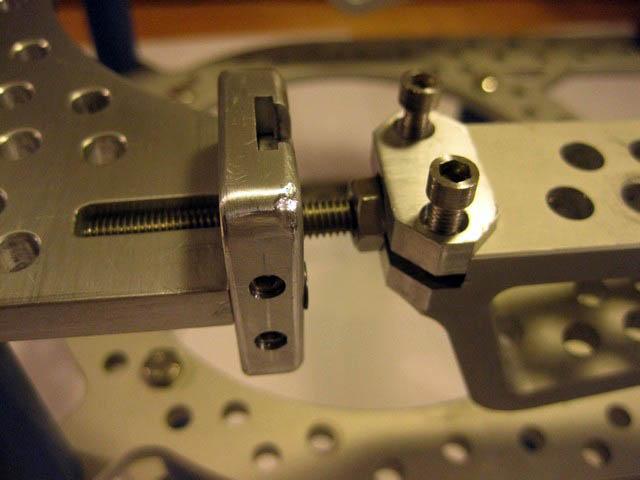

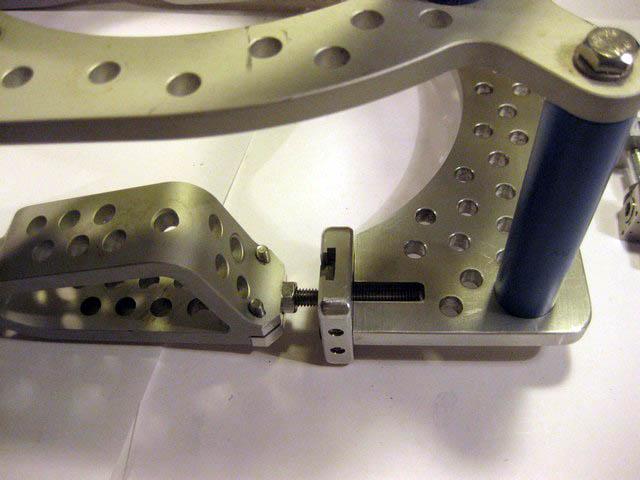

November 2014 Added Base Plate and Lock Spring For The Lever.

The base plate retains the gears better than dowel pins and ring grooves.

- Current Spring Clip

Functional Prototype Taking Shape with good range of motion.

- MDPO Dynamic Arch Assembly

Fifth Stage Redesign Fine Adjustment And Cam Lever

- Adjustment Knobs and Locking Levers

Forth Development Stage, Fabricating the Ball Joint Fine Adjustment.

- Gear form Cutter

- Adjustment Knobs

- Gear W/Teeth

- Gear W/Teeth

- Lever and Worm Gear

- Bored for lever

Third Development Stage, Dynamic Connecting Plate.

Second Development Stage, Dynamic Arch Hinge.

- MDPO Dynamic Hinge

Initial Development Stage, Dynamic Ball Joint and Dynamic Column.

- Ball and axis pins